Airplanes have transformed the way we travel, connecting the world like never before. They are marvels of engineering, and many people often wonder how these massive, complex machines are created. In this article, we will explore the process of how an airplane is made from its initial design to its final assembly and takeoff.

Design and Development

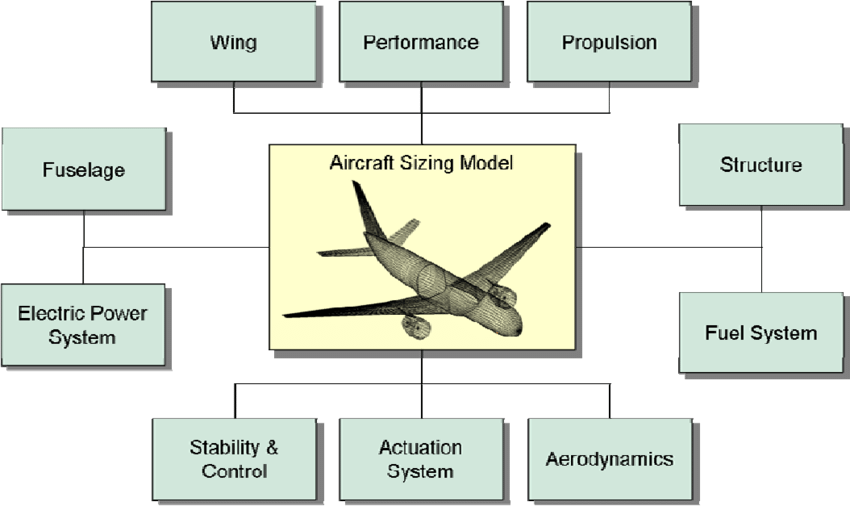

The first step in building an airplane is its design. Engineers and designers work together to create a concept for the aircraft, taking into consideration the intended purpose of the plane, such as passenger travel or cargo transport. They must also factor in aspects like fuel efficiency, aerodynamics, and materials to be used in the construction.

During the design phase, engineers use advanced computer software to create 3D models of the airplane, simulating its performance and testing various aspects like stability, lift, and drag. This process can involve a significant amount of trial and error, as designers work to refine their concepts and create the most efficient and effective airplane possible.

Manufacturing and Assembly

Once the design is finalized, the manufacturing process begins. Airplanes are made from a wide variety of materials, including metals like aluminum and titanium, composites like carbon fiber, and even advanced plastics. These materials are chosen for their strength, lightweight properties, and resistance to corrosion.

The manufacturing process involves several steps:

- Cutting and shaping: Materials are cut, shaped, and formed into individual components, such as wings, fuselage sections, and tail sections. This can be done using various methods, including machining, forging, and casting.

- Joining: Components are joined together using techniques like welding, riveting, or bonding with adhesives. Some advanced aircraft designs even utilize composite materials that are “cooked” together in large ovens, creating a seamless structure.

- Finishing: After the main structure of the airplane is assembled, it’s time to add the finishing touches. This includes installing the engines, avionics, electrical systems, and other essential components. The airplane is then painted, and its interior is fitted with seats, galleys, and other amenities.

- Testing: Before an airplane can take to the skies, it must undergo rigorous testing. This includes ground tests to ensure that all systems are functioning correctly, as well as flight tests to verify its performance, handling, and safety. If any issues are discovered during testing, they must be addressed before the airplane can be approved for commercial use.

The Final Product

Once the airplane has passed all tests and received the necessary certifications, it’s ready for delivery to its new owner. This could be an airline, cargo company, or even a private owner. The airplane is now ready to take to the skies and transport passengers, cargo, or both, safely and efficiently.

Conclusion

The process of how to build an airplane is a complex and fascinating one, involving a combination of design, engineering, and manufacturing. From the initial concept to the final assembly and testing, it takes a great deal of expertise and innovation to create these incredible machines. So, the next time you board a flight, take a moment to appreciate the incredible work and ingenuity that goes into making an airplane.